Why are there different Formats of Sheave Gauges?

In order to ensure optimal performance of sheaves and wire rope a complete range of sheave gauges should be used. We stock gauges in the following formats:

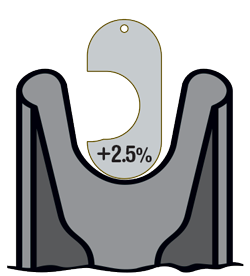

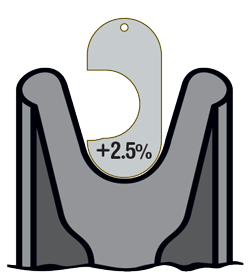

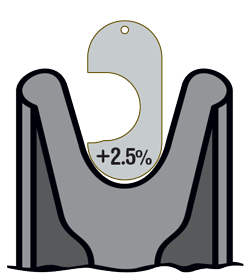

+2.5% API Sheave Gauges are used to determine when Maximum and Excessive Wear levels has been reached.

+5% Sheave Gauges are legacy format. They should fit snugly in new or re-machined sheaves. If correctly sized wire rope is run through the sheaves there will be a minimum of friction which should extend the life of the wire rope.

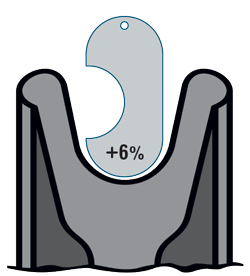

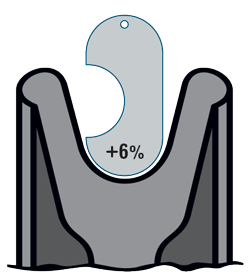

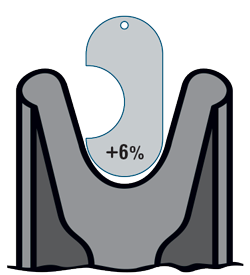

+6% API Sheave Gauges measures the minimum size for a new sheave.

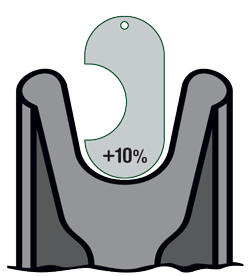

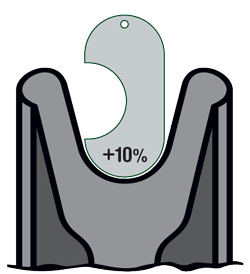

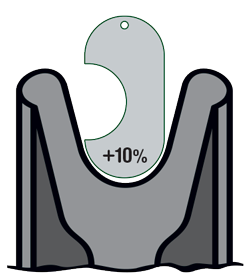

+10% API Sheave Gauges measures the maximum size for a new sheave.

Other formats can be custom made upon request.

| NOMINAL WIRE GAUGES |

GO NO/GO WIRE GAUGES |

MEASURE ACROSS THE

OUTER EDGE OF TWO STRANDS

|

CORRECT

Wire Rope should not fit in Gauge

|

USE LARGER GAUGE

|

ROUGED WIRE ROPE

Replace if Cable Shows Rust

|

USE SMALLER GAUGE

|

REPLACE WIRE ROPE

When Cable Fits in Gauge

|

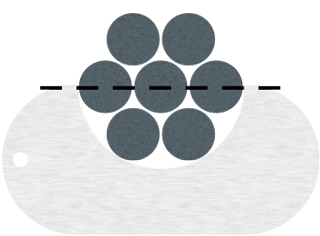

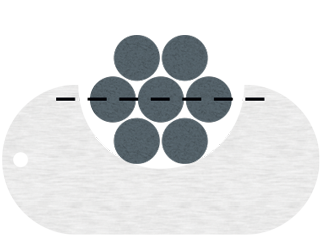

Using a Nominal

Wire Rope Gauge

Only use a wire rope gauge to determine approximate wire rope diameter.

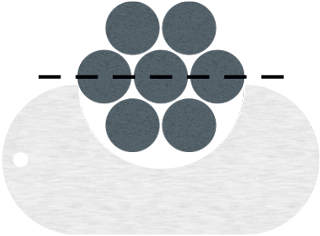

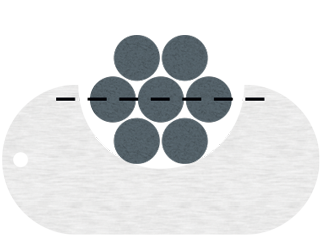

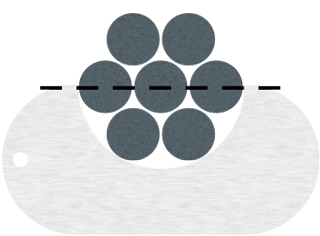

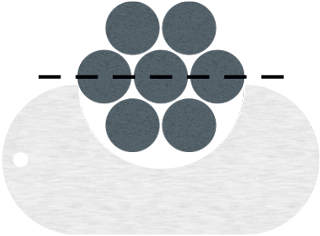

- Align the gauge so that the wire can be measured from the outer edge of one strand to the edge of the strand directly opposite.

- If the wire rope does not fit in the gauge, use a larger gauge until the wire rope fits in the gauge.

- Shine a light behind the gauge.

- If you can see light between the gauge and the wire rope repeat with a smaller size gauge until no light shows.

For more accurate measurements use a machinist’s caliper or micrometer.

|

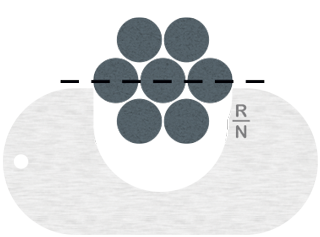

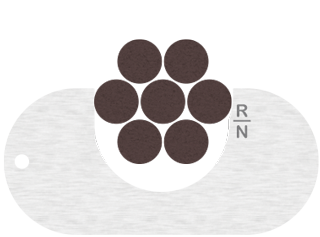

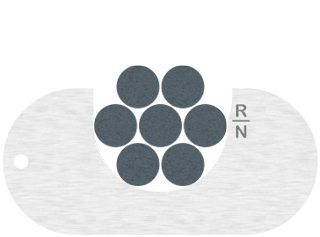

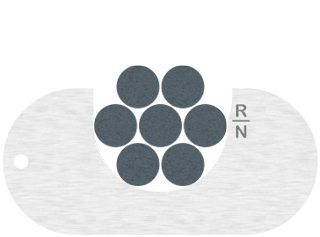

Using a Go/NoGo

Wire Rope Gauge

Only use a wire rope gauge to determine approximate wire rope diameter.

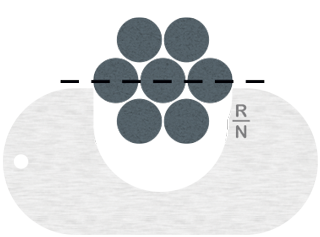

- Align the gauge so that the wire can be measured from the outer edge of one strand to the edge of the strand directly opposite.

- If the wire rope does not fit in the gauge it is still above the nominal -3.125% threshold.

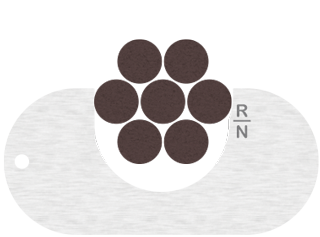

- If the wire rope fits in the first notch it should be replaced if the cable shows rust (rouge).

- If the wire rope reaches to the bottom of the gauge it should be replaced.

For more accurate measurements use a machinist’s caliper or micrometer.

|